Automotive industry

Automotive industryCNC Solutions for Medical Devices

Medical Devices Solution

Medical Devices

Precision machining to protect your health

In the rapidly developing medical device industry, the quality of products is directly related to the health and safety of patients. As a leading machine tool manufacturer, ZOPO is committed to providing excellent machining solutions for the medical device industry through high-precision and high-performance machine tools.

ZOPO QUALITY: Our machines are widely used in the production of medical devices, thus ensuring that every product meets strict quality standards.

Advantages

Leading-edge technology and processing

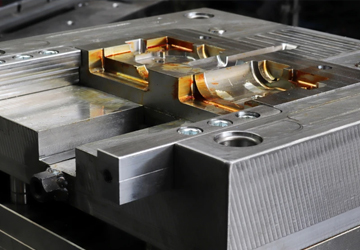

High Precision Machining: Medical device designs often require extremely high tolerances and precision. Our CNC machines use advanced machining technology to achieve micron-level precision, ensuring that every component of a medical device fits perfectly and works optimally.

Diversified machining capability: In the face of diversified medical device products, our machines have strong adaptability to support the machining of a variety of materials (e.g. stainless steel, titanium alloy, plastics, etc.) to meet the needs of different products.

Strict quality control: Tropicana is committed to providing customers with machine tools that meet only international standards. We have implemented a strict quality management system to ensure that every machine tool is thoroughly tested and verified before it leaves the factory so that customers can use it with confidence.

One-stop technical support: our professional team will provide a full range of services from project consulting, machine tool selection to post maintenance and technical support to ensure that customers have no worries in the production process.

Factory visitApplication area

Surgical instruments: Precision surgical instruments such as knives, grippers and probes require the highest level of machining accuracy, and our machines ensure that every product meets industry regulations and standards.

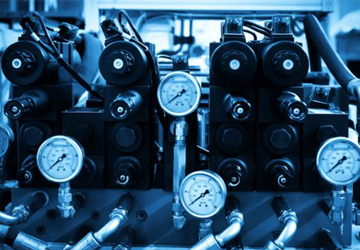

Medical device components: For the machining of components for CT, MRI and other large medical equipment, we provide highly efficient machining solutions to help with the rapid production and maintenance of equipment.

Implant Manufacturing:For products such as joint replacements and dental implants, our machines are capable of processing high-strength and biocompatible materials to ensure the performance and safety of implants.

Reagents and Consumables:The demand for all types of reagents and disposable consumables in the medical industry is on the rise, and our machines support the precise processing of plastic and rubber materials.

Case Medical devices

Create Value Together,Multiply Benefits

- High Precision

- High Stability

- Beat Optimization

- High Processing Efficiency

Will Increase Your Income Soon:

$:123456.00

Apply For Free Proofing

- Free Sample

- Tel

- Tel

- *Title

- *Content