Automotive industry

Automotive industryCNC Solutions for the Hydraulic Industry

Hydraulic Industry Solution

Hydraulic Industry

Empowering Hydraulic Transmissions to Improve Industrial Efficiency

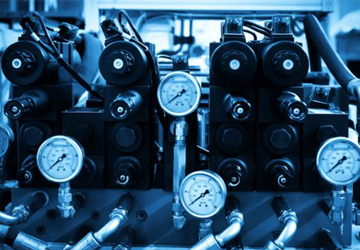

Hydraulic transmission technology is rapidly rising in the global manufacturing industry, with its powerful power transmission, precise control capabilities and excellent reliability, hydraulic systems are widely used in construction machinery, automotive manufacturing, aerospace and other industries. As an indispensable and important part of the hydraulic system, the precision machining capability of machine tools is the basis for guaranteeing the high performance of hydraulic components.

Advantages

Leading-edge technology and processing

High-precision machining: Our machine tools are equipped with advanced CNC systems, high rigidity design and high-precision cutting tools to achieve precision machining of hydraulic components and ensure that the products meet the industry standards.

Flexible production capacity: Whether for high volume production or small customised batches, our machines offer excellent adaptability to meet the needs of our customers in different industries by improving their production processes.

Reliable Stability: Our machines are subjected to stringent quality control and prolonged testing to ensure that they maintain excellent stability and durability under intense production environments.

Application area

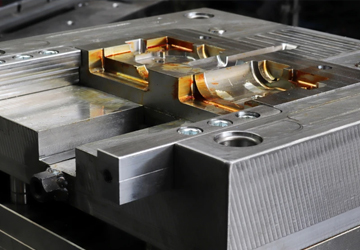

Hydraulic cylinder manufacturing: Key components such as the outer barrel and piston of hydraulic cylinders require high precision machining by machine tools. With the help of advanced CNC lathes and milling machines, we ensure strict control of each component in terms of dimensions, tolerances and surface roughness, in order to improve the working efficiency and service life of hydraulic cylinders.

Control valve parts machining:Hydraulic control valves are important components for regulating hydraulic systems. The precise machining capability of machine tools can effectively improve the sealing performance of the valve body and ensure that the hydraulic system remains stable over long periods of operation. Through fine milling and drilling processes, we can realise more complex geometric designs to enhance valve performance.

Production of pump bodies and components: Hydraulic pump is the heart of the hydraulic transmission system, and its key components (such as pump casing, rotor, etc.) require very high precision in the machining process. CNC machine tools can fully meet this demand and improve the overall performance of the pump and fluid efficiency.

Case Hydraulic industry

Create Value Together,Multiply Benefits

- High Precision

- High Stability

- Beat Optimization

- High Processing Efficiency

Will Increase Your Income Soon:

$:123456.00

Apply For Free Proofing

- Free Sample

- Tel

- Tel

- *Title

- *Content