Automotive industry

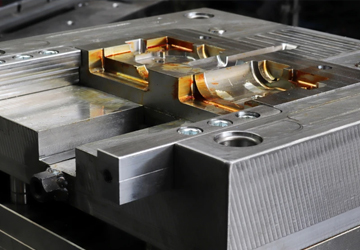

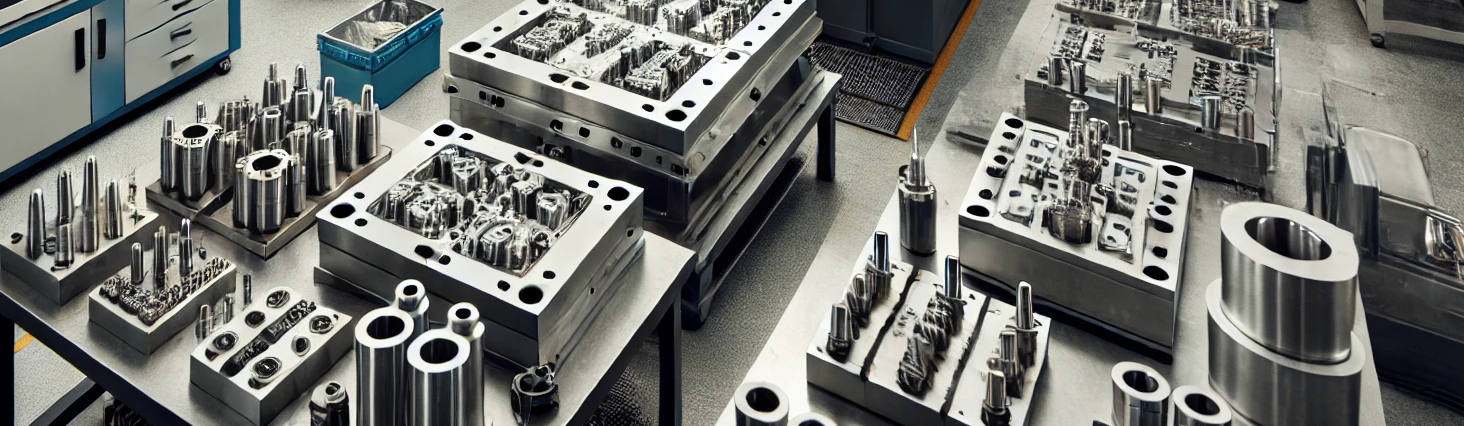

Automotive industryCNC Applications for Mold Manufacturing

Mold Manufacturing Solution

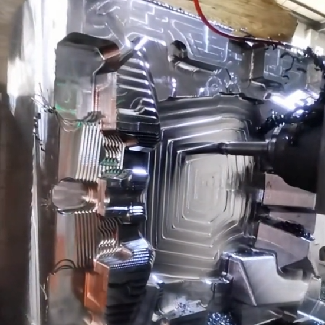

Mold Manufacturing

Excellent machine technology for precision and efficiency in mold and die manufacturing

In the mold and die manufacturing industry, precision and reliability are critical. As the industry's leading machine tool manufacturer, our machines provide the ideal solution for mold and die making with their superior technology and superior performance.

Advantages

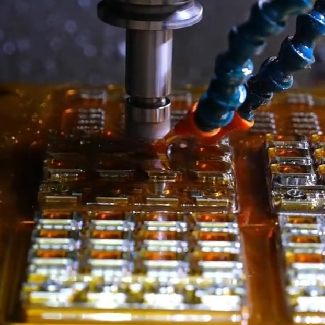

Leading-edge technology and processing

High-precision machining: Adopting the latest CNC technology and high rigidity structure ensures that high precision is maintained during the machining process and meets the strict requirements for dimensional tolerances and surface quality in mould manufacturing.

Powerful cutting ability: Equipped with advanced power head and tooling system, it has excellent cutting ability to handle a wide range of complex materials, including high hardness steels and alloys, to ensure the long term durability and reliability of the moulds.

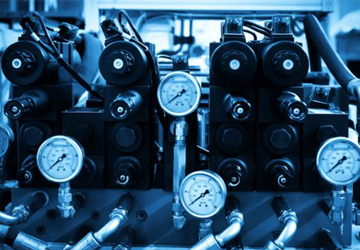

Stable performance: Considering the stability and durability of long-term operation, it maintains stable performance under both high load and long-time working conditions, reducing the failure rate and maintenance costs.

Intelligent control system: Equipped with an intelligent CNC system, it provides an intuitive operator interface and automated machining functions to enhance productivity and reduce human errors.

Flexible customised solutions: Individual customised services according to the customer's specific needs, including machine configuration, fixture design and machining process optimisation, to ensure the best possible machining results.

Factory visitApplication area

Automotive molds: In the automotive manufacturing industry, our machines are capable of machining complex automotive molds, including body shells, interior parts, and structural parts, ensuring high precision and high strength molded products.

Electronic molds: In the production of electronics, our machines are used to manufacture precision molds for electronic components such as mobile phone housings, connectors and display assemblies, providing consistent and reliable processing quality.

Appliance molds: In the electrical appliances industry, our machines are used to produce molds for a wide range of home appliances, including refrigerators, washing machines and air conditioners, helping our customers to improve productivity and product quality.

Industrial molds:We also provide support for a wide range of industrial molds, including machining molds and plastic injection molds, to meet the processing needs of different application scenarios.

Case Mold Manufaturing

Create Value Together,Multiply Benefits

- High Precision

- High Stability

- Beat Optimization

- High Processing Efficiency

Will Increase Your Income Soon:

$:123456.00

Apply For Free Proofing

- Free Sample

- Tel

- Tel

- *Title

- *Content